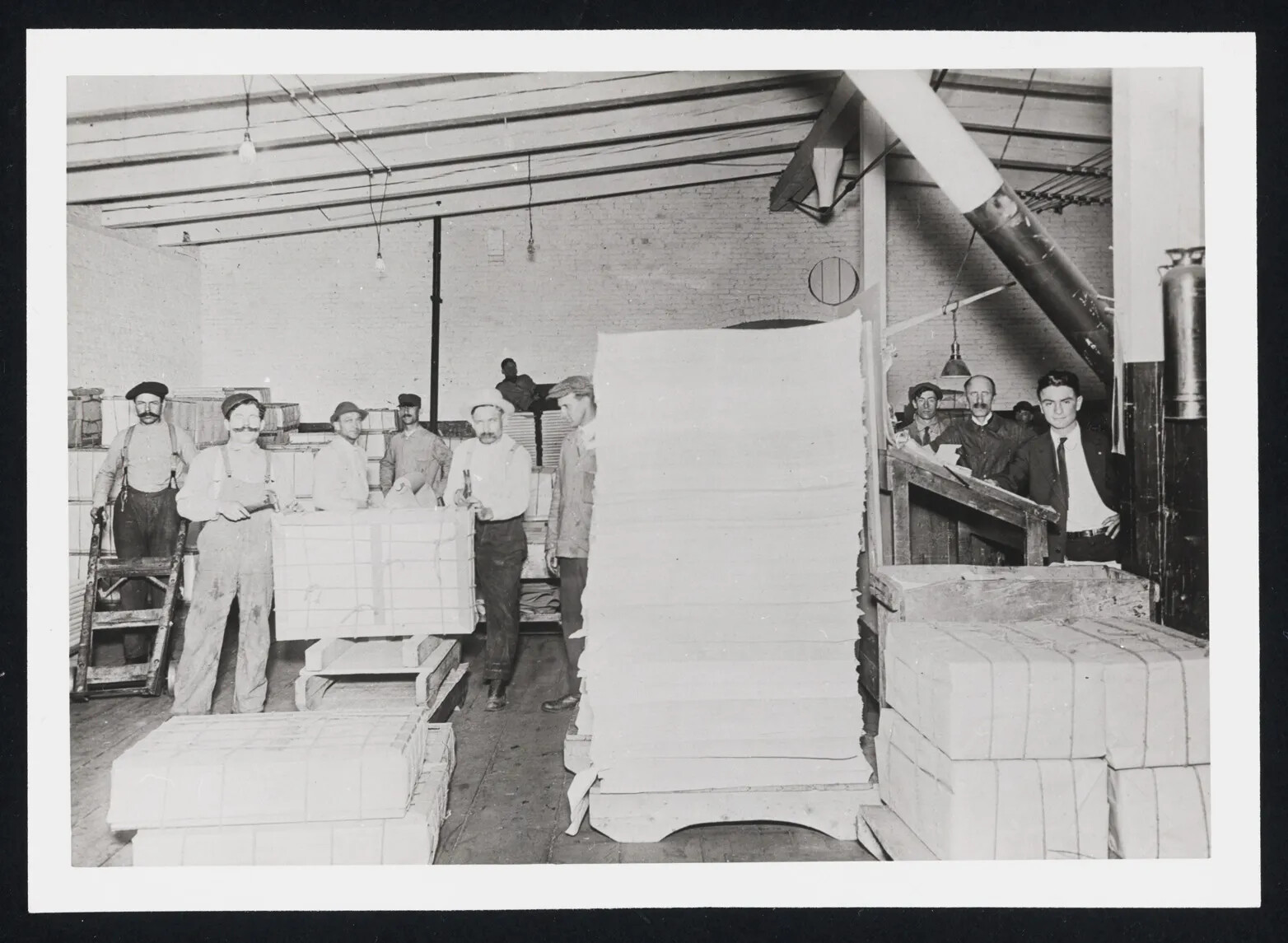

Big Factories and New Industries, 1820–1920

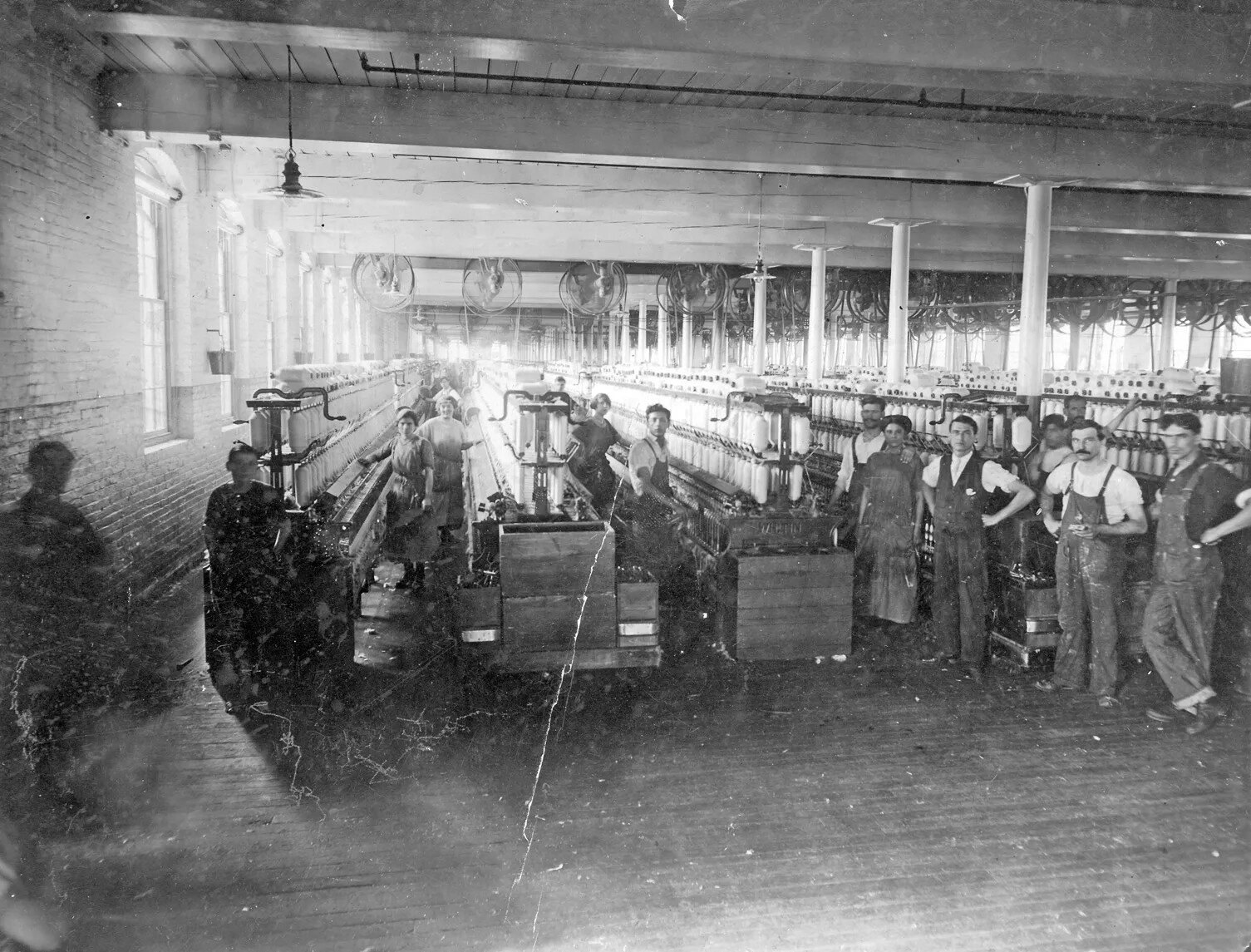

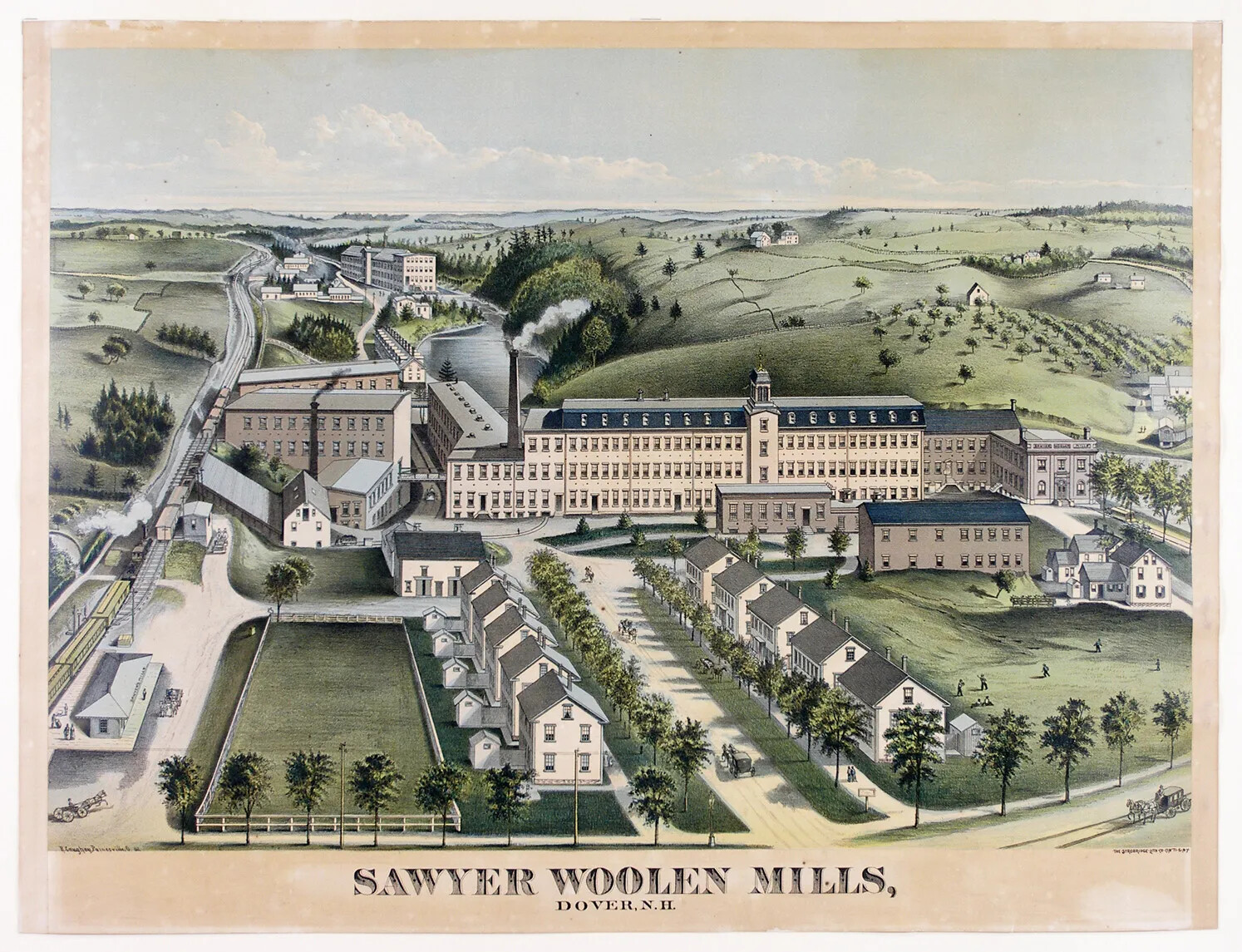

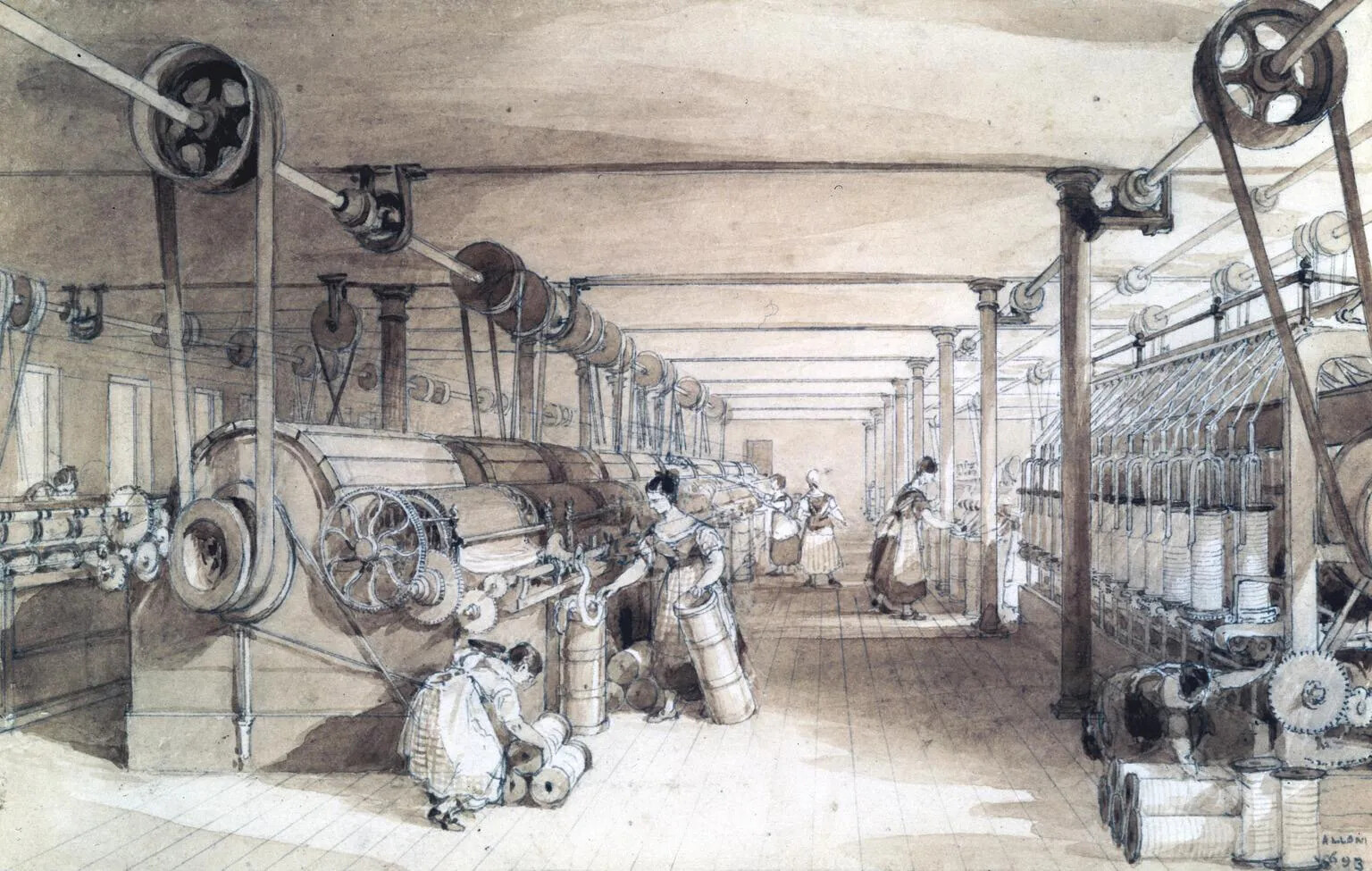

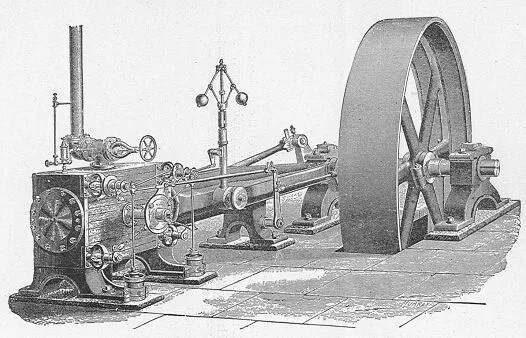

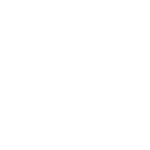

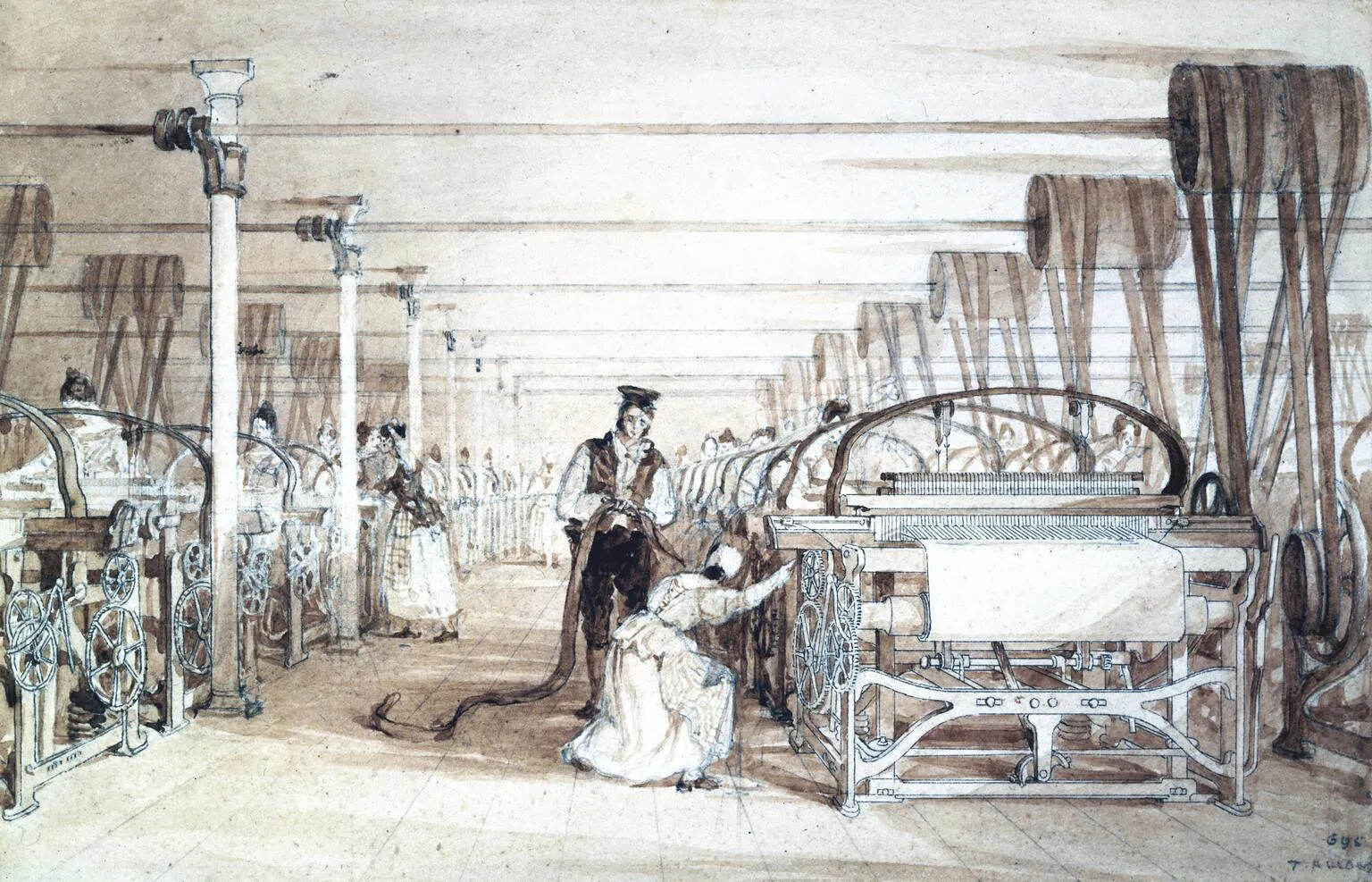

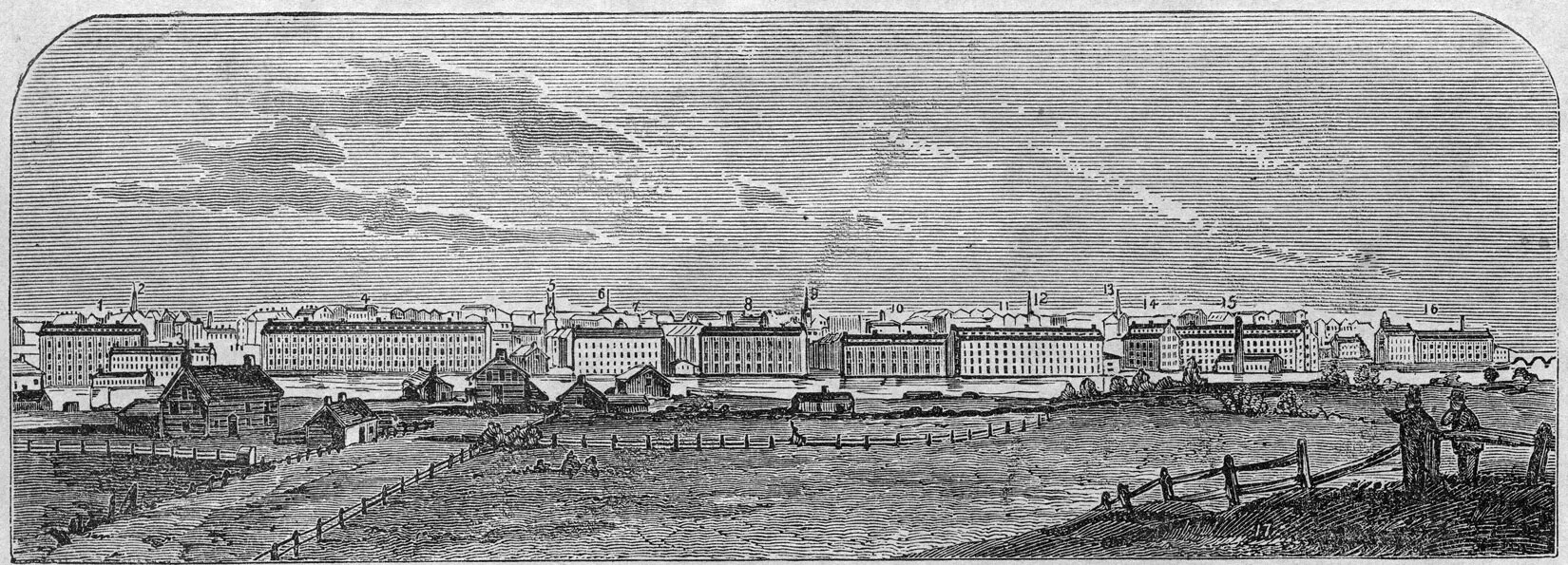

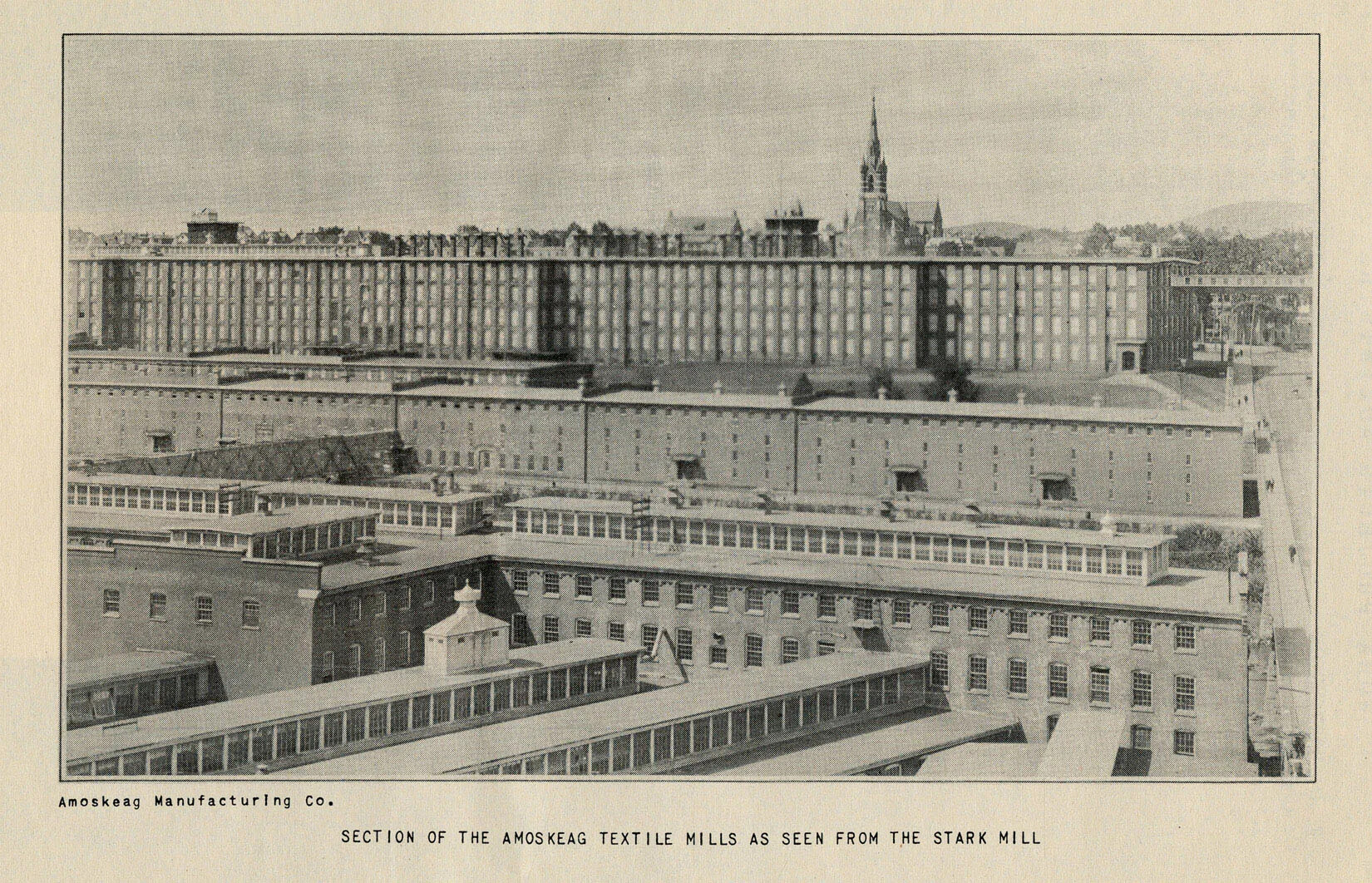

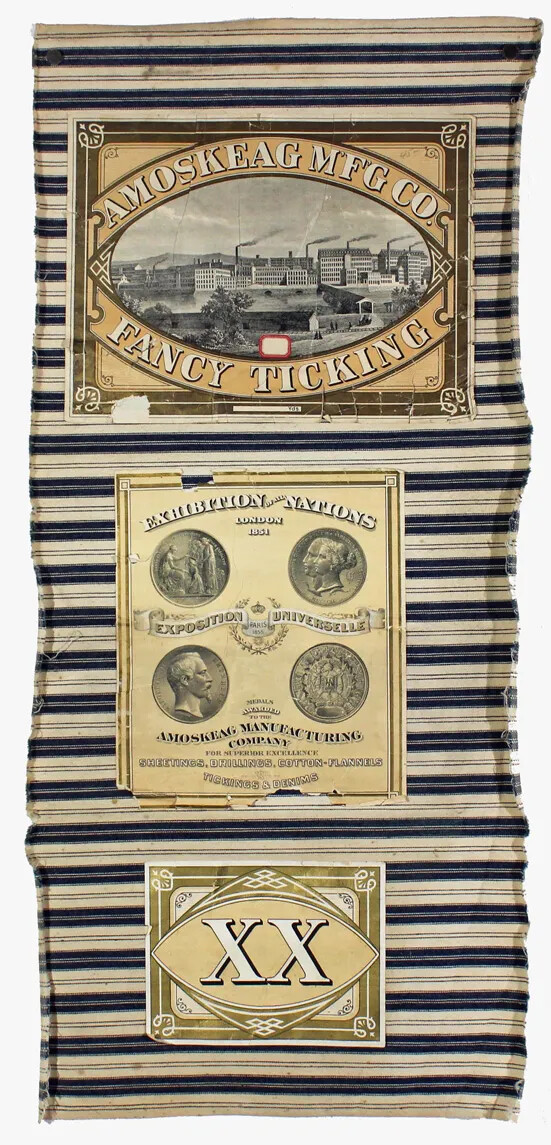

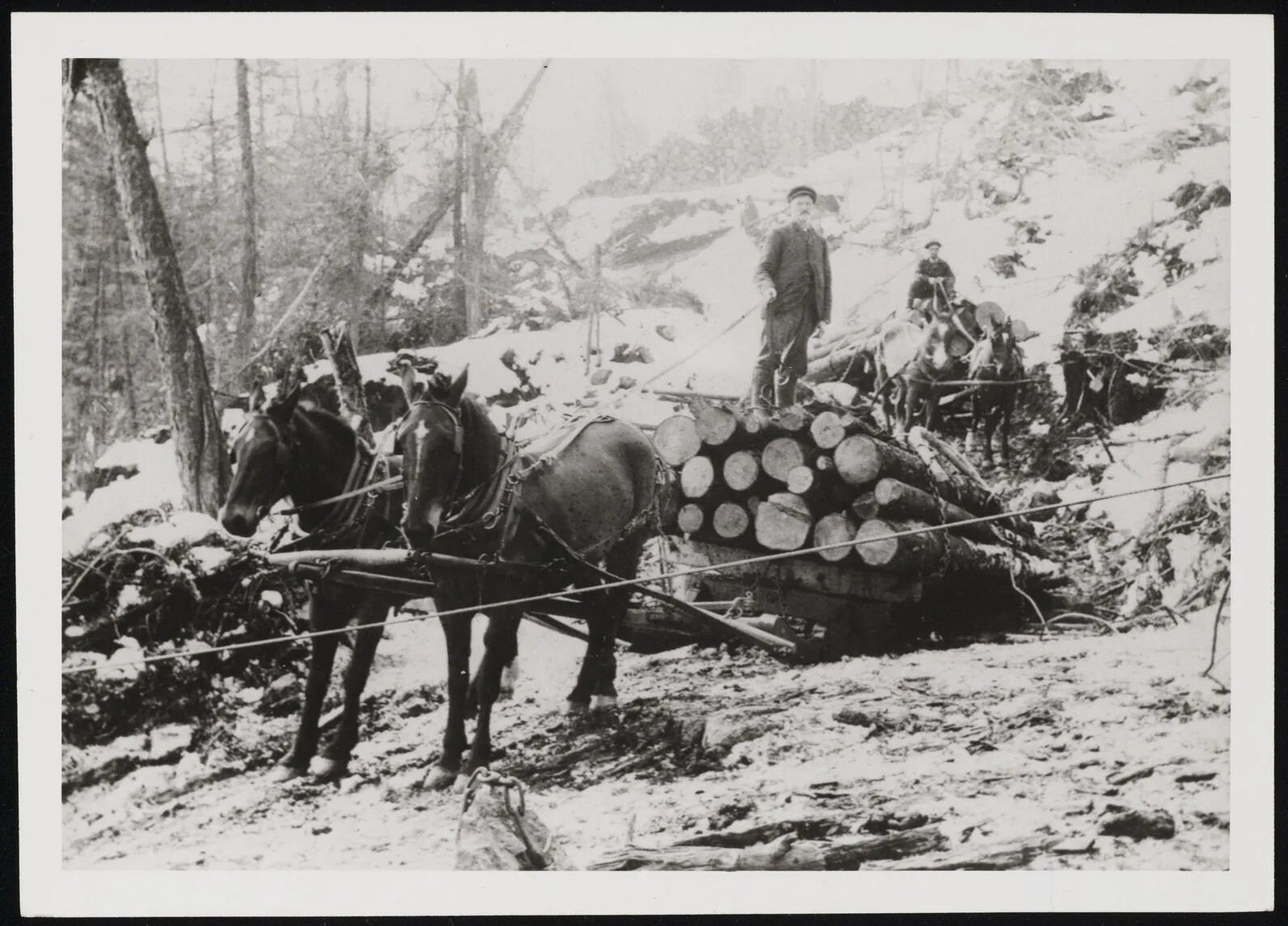

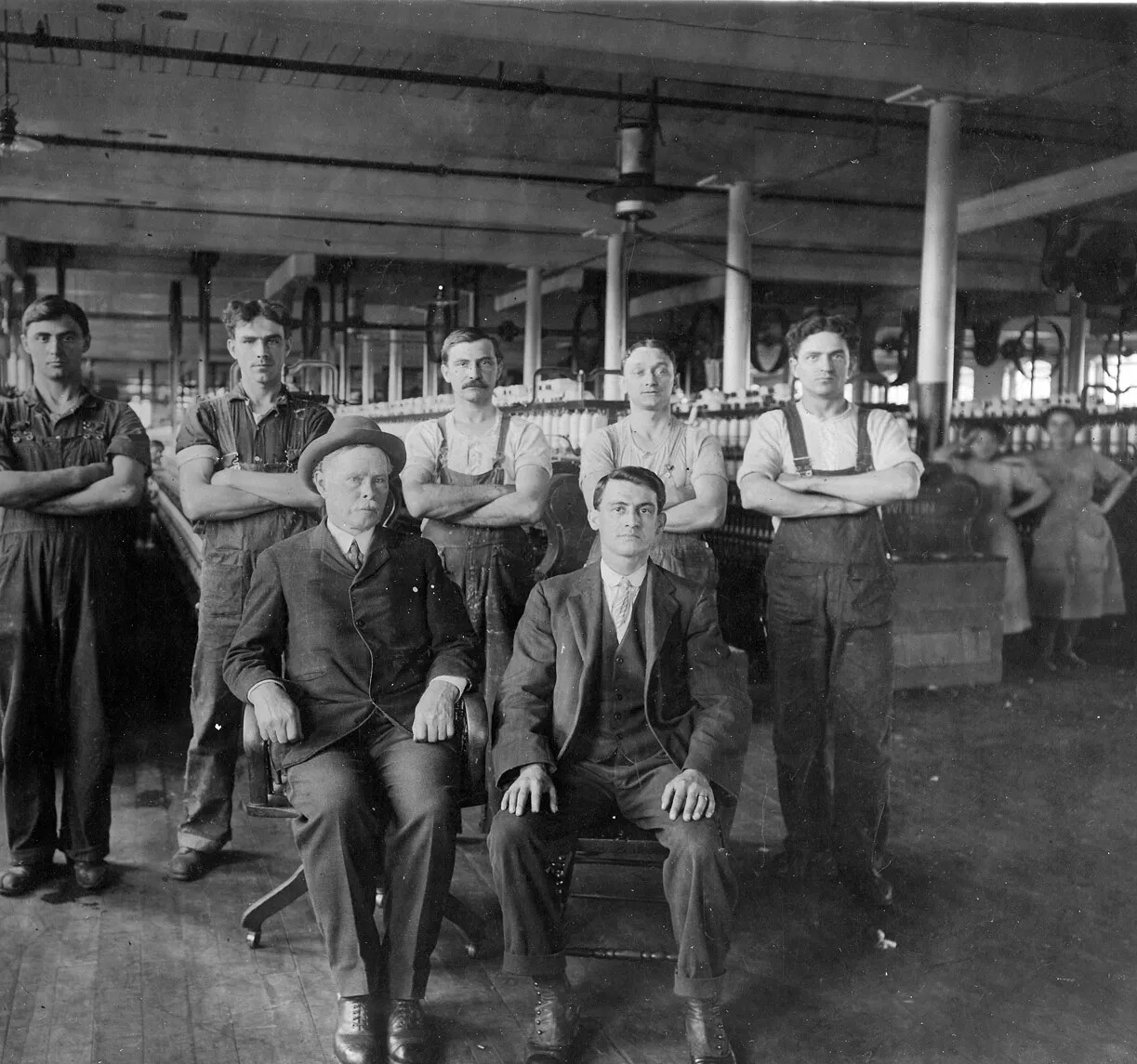

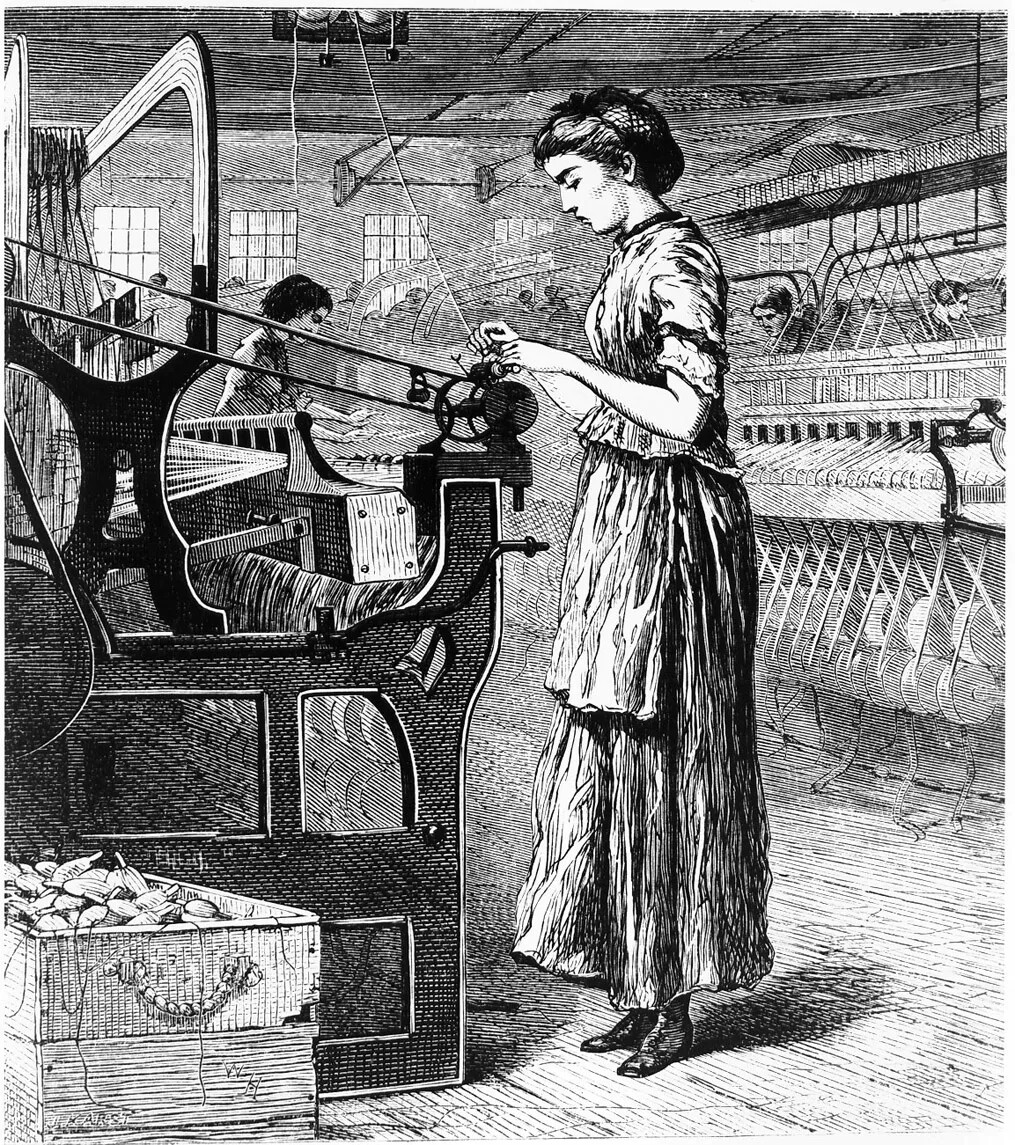

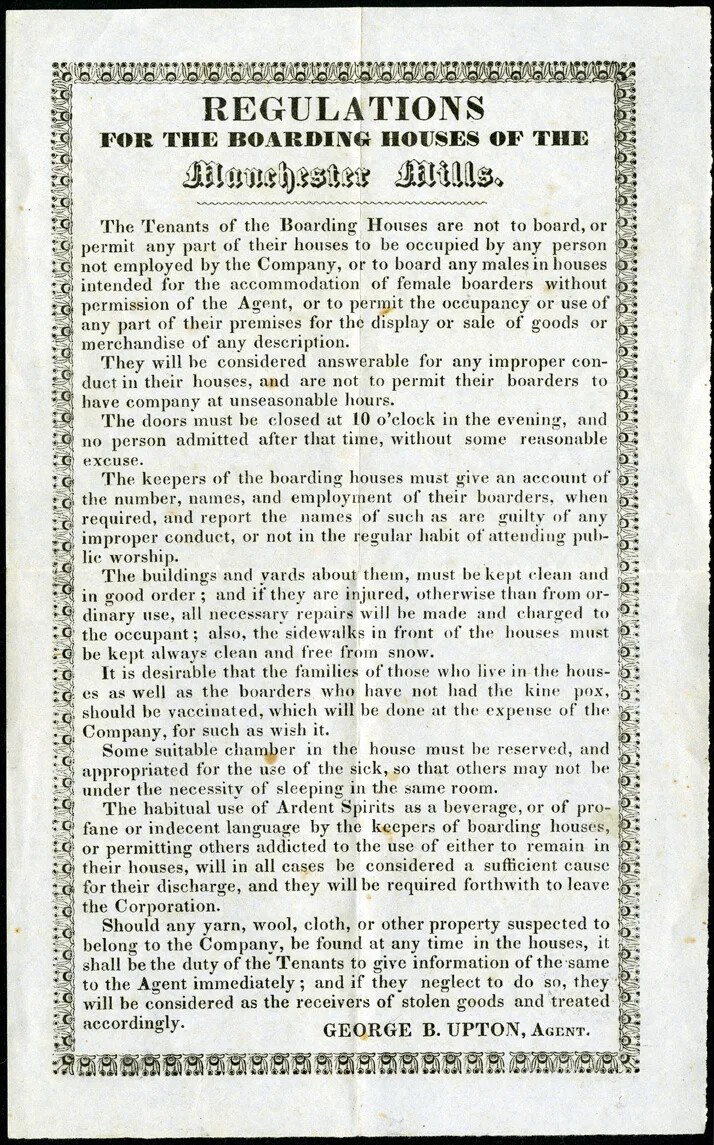

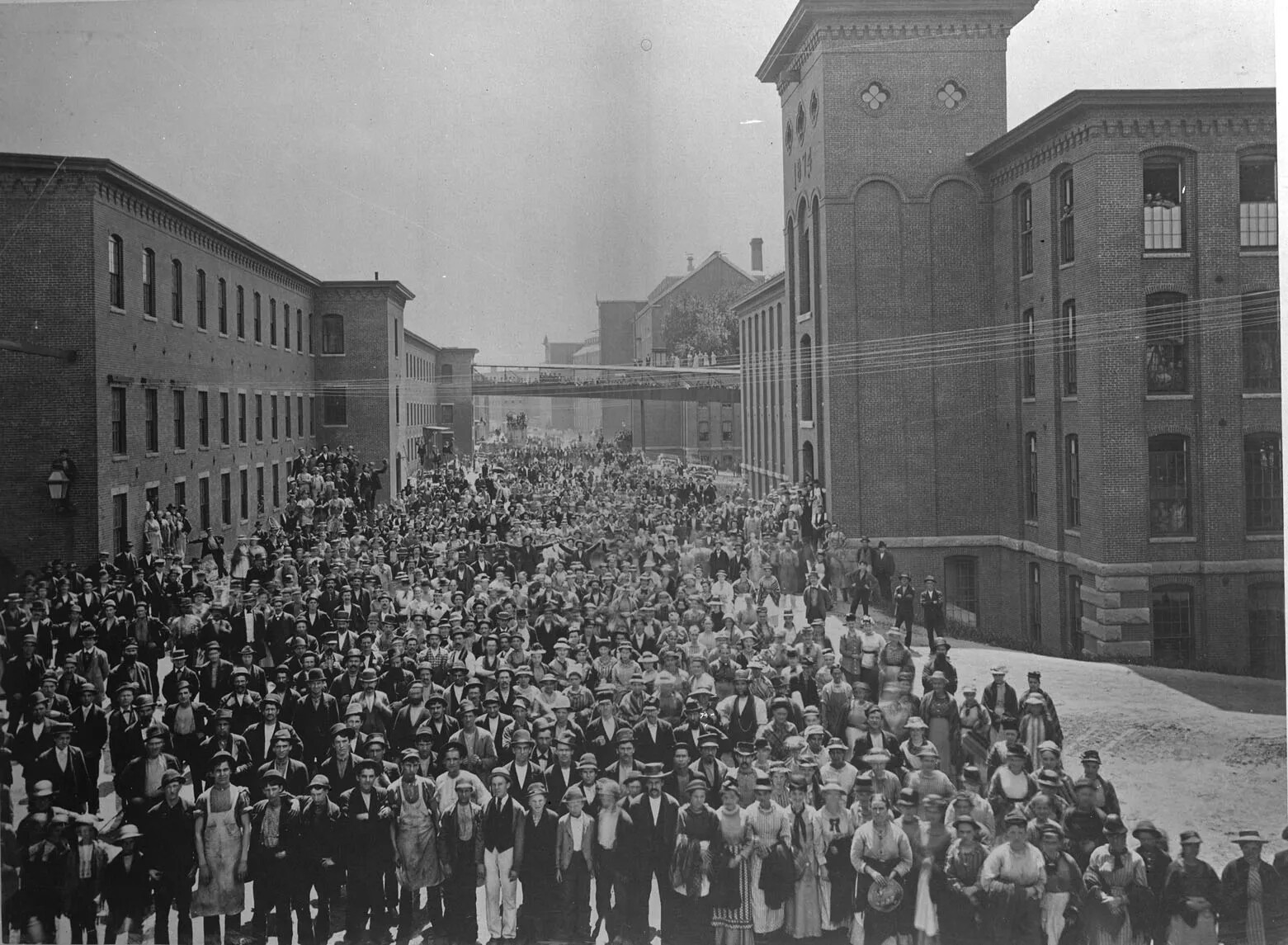

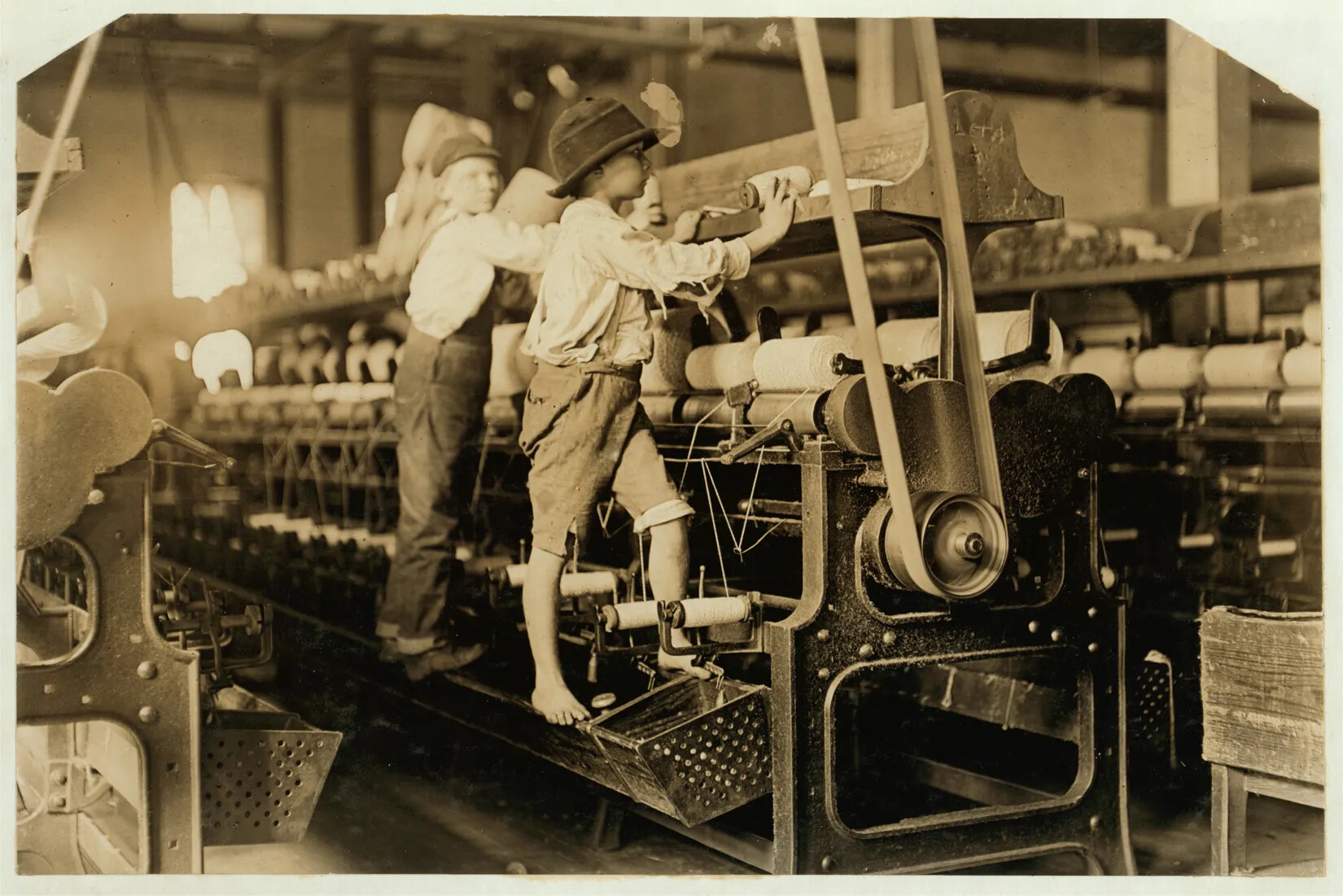

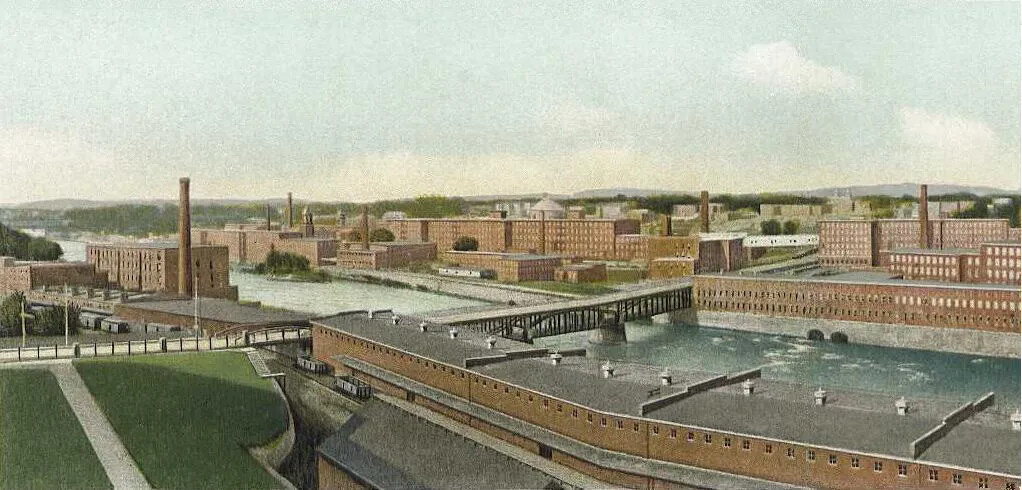

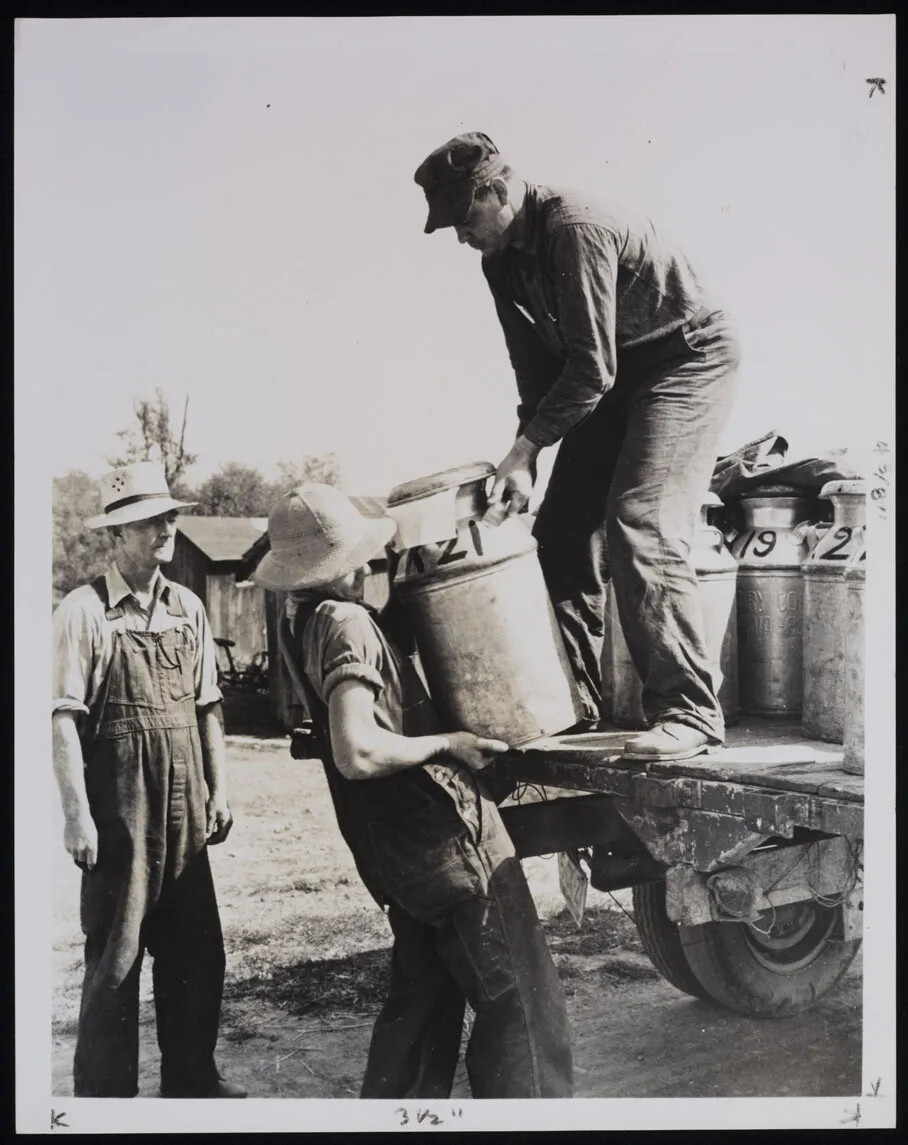

In the 19th century, New Hampshire was one of the first states in America to build factories. This period of time was known as the Industrial Revolution, when factories made it possible for people to make all sorts of products faster and cheaper than ever before. The people in the factories used machines to help them do their work. Even with the machines, working in a factory was hard and very different from the kind of work people had done before. The Industrial Revolution changed more than just the way people worked, though.

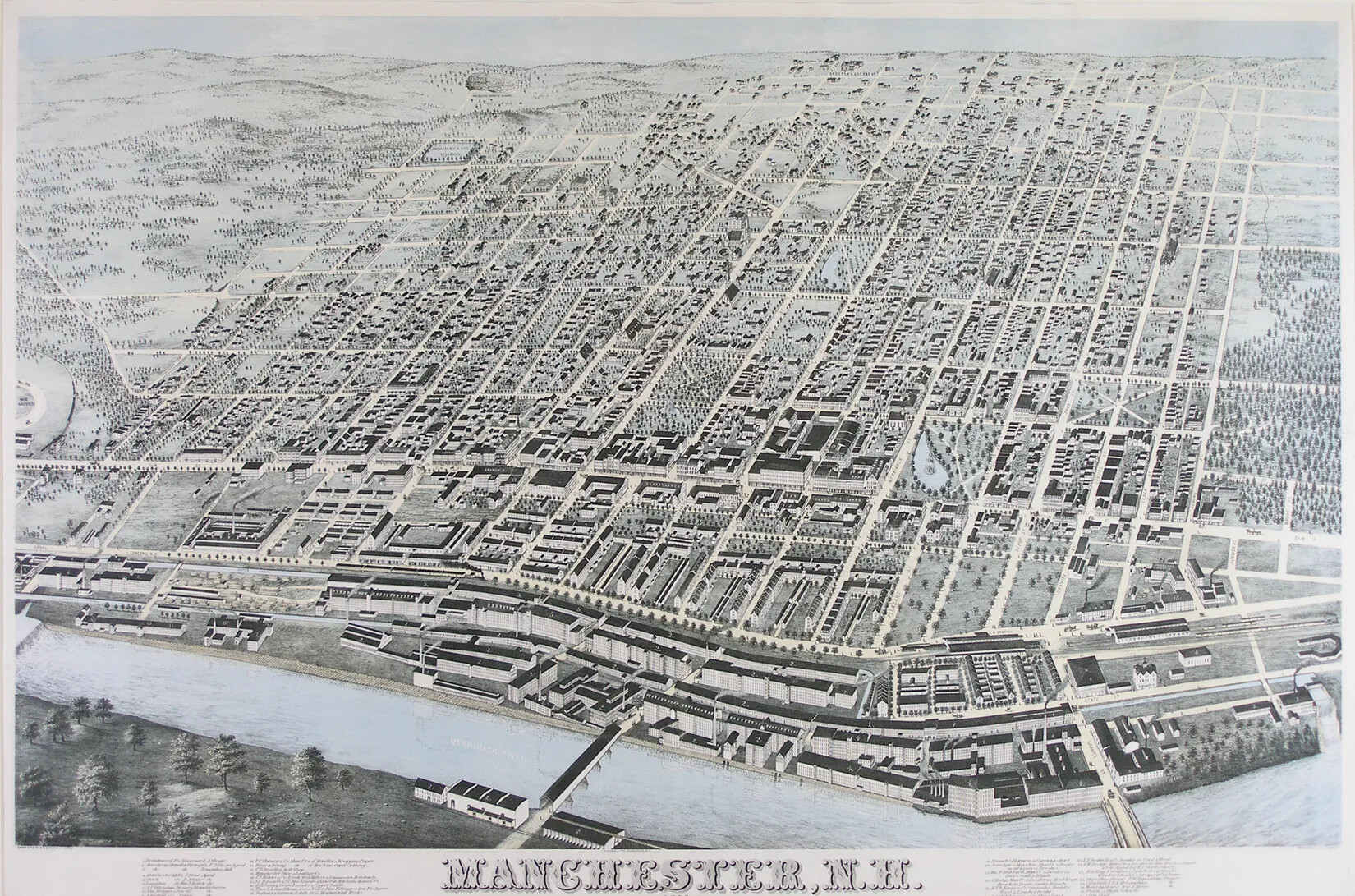

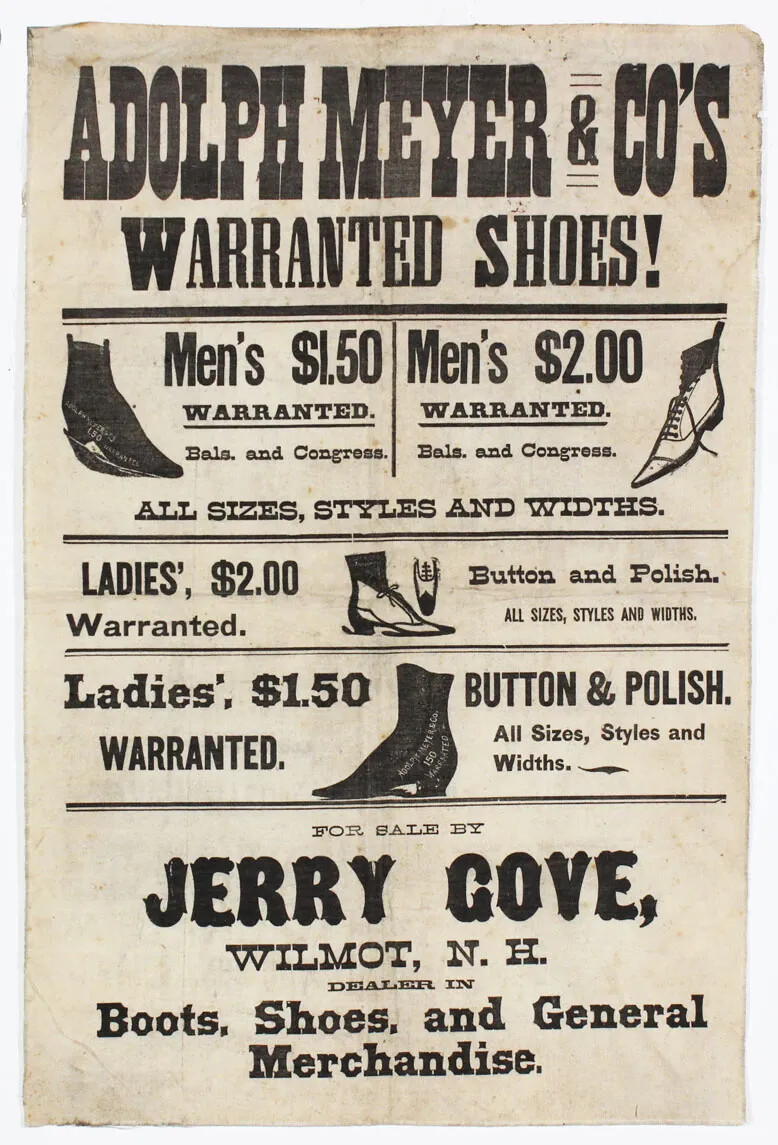

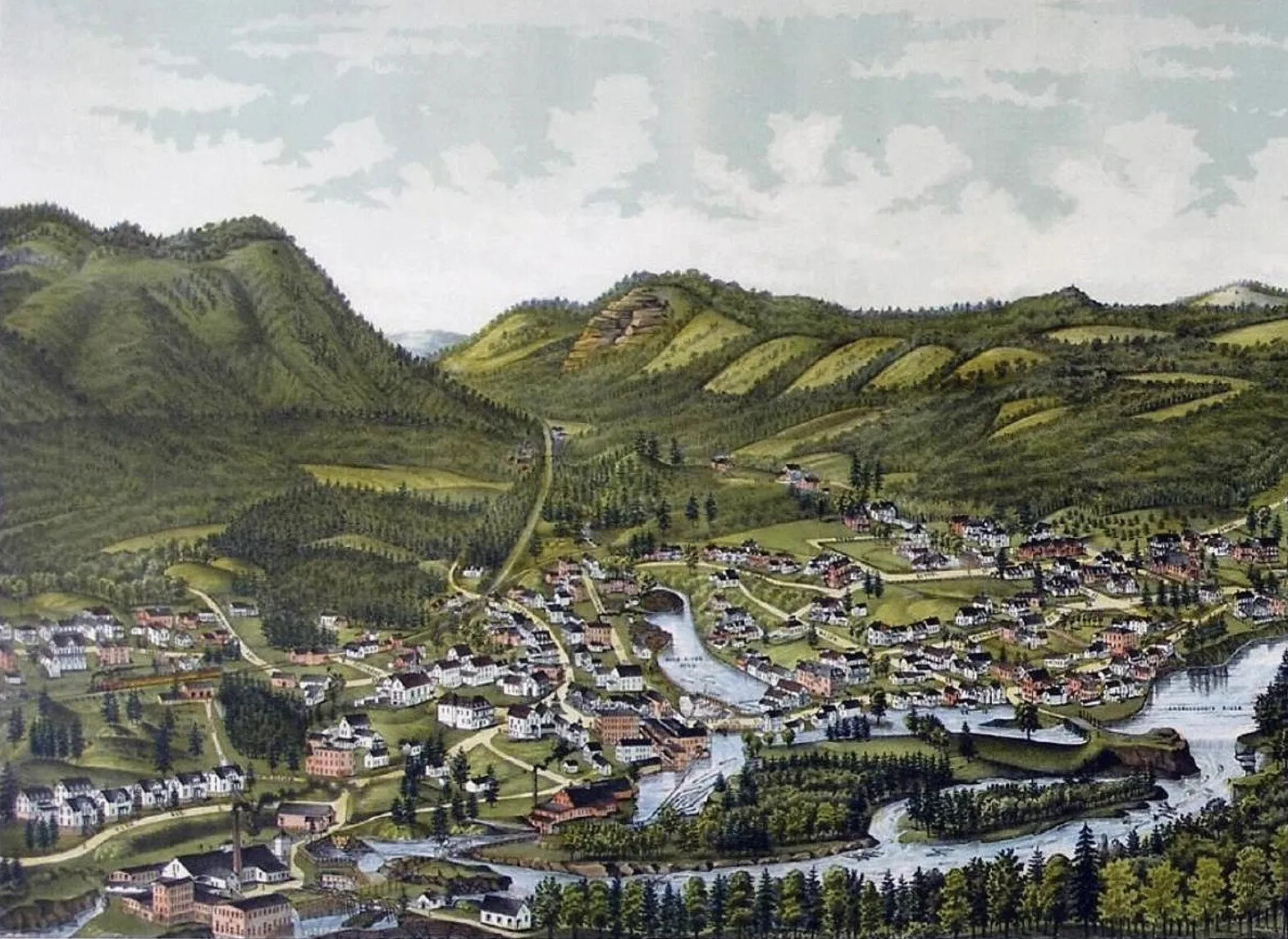

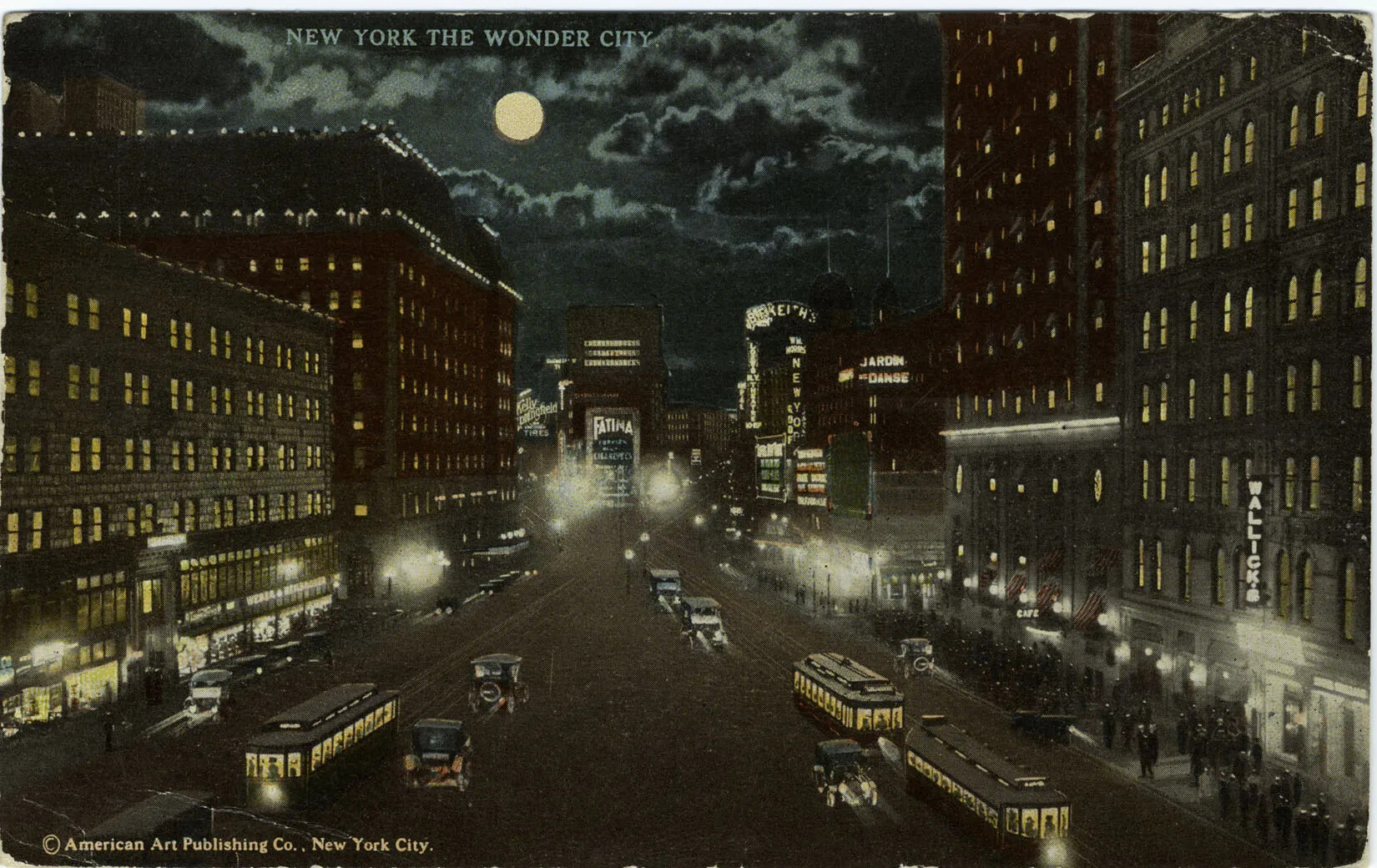

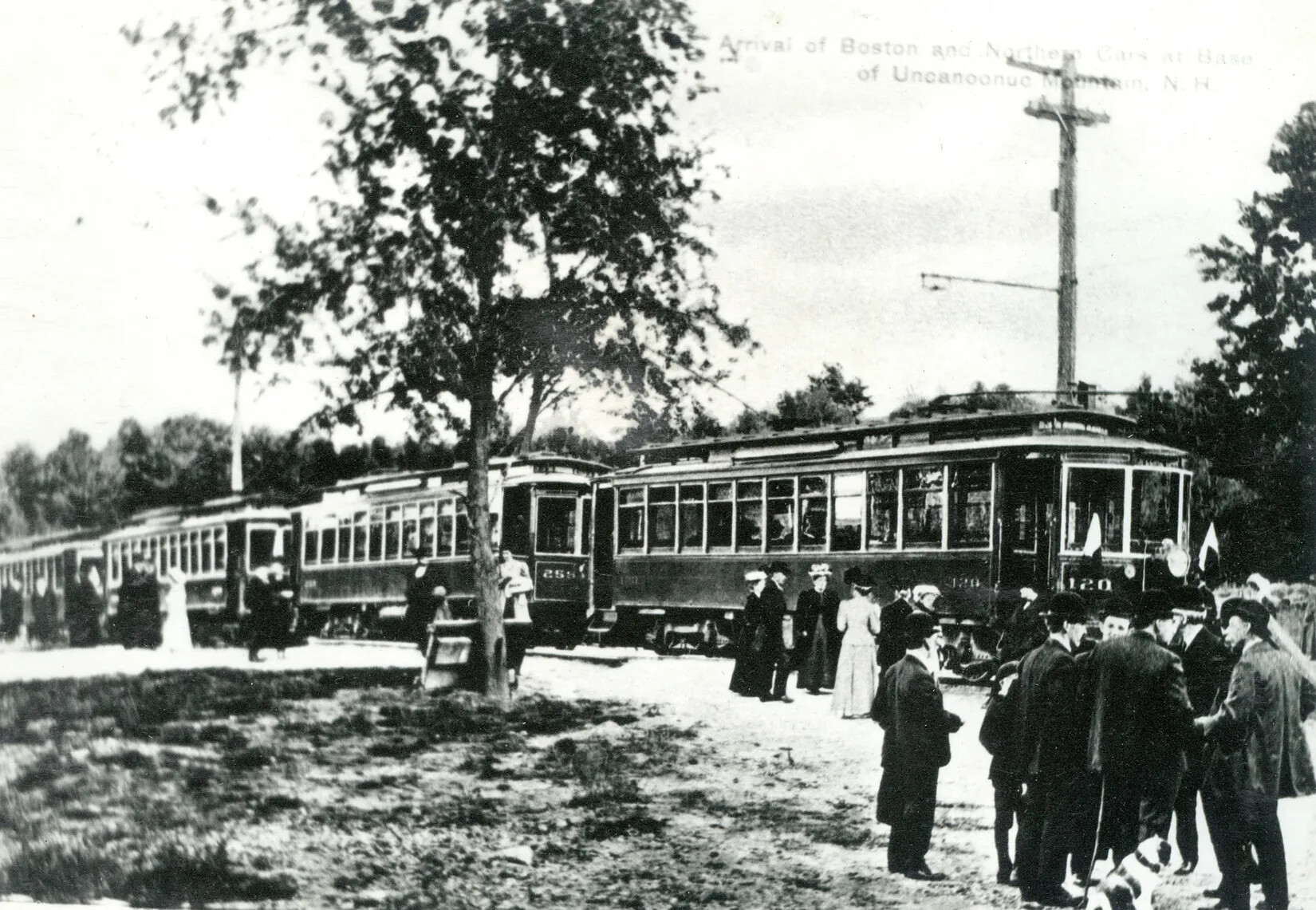

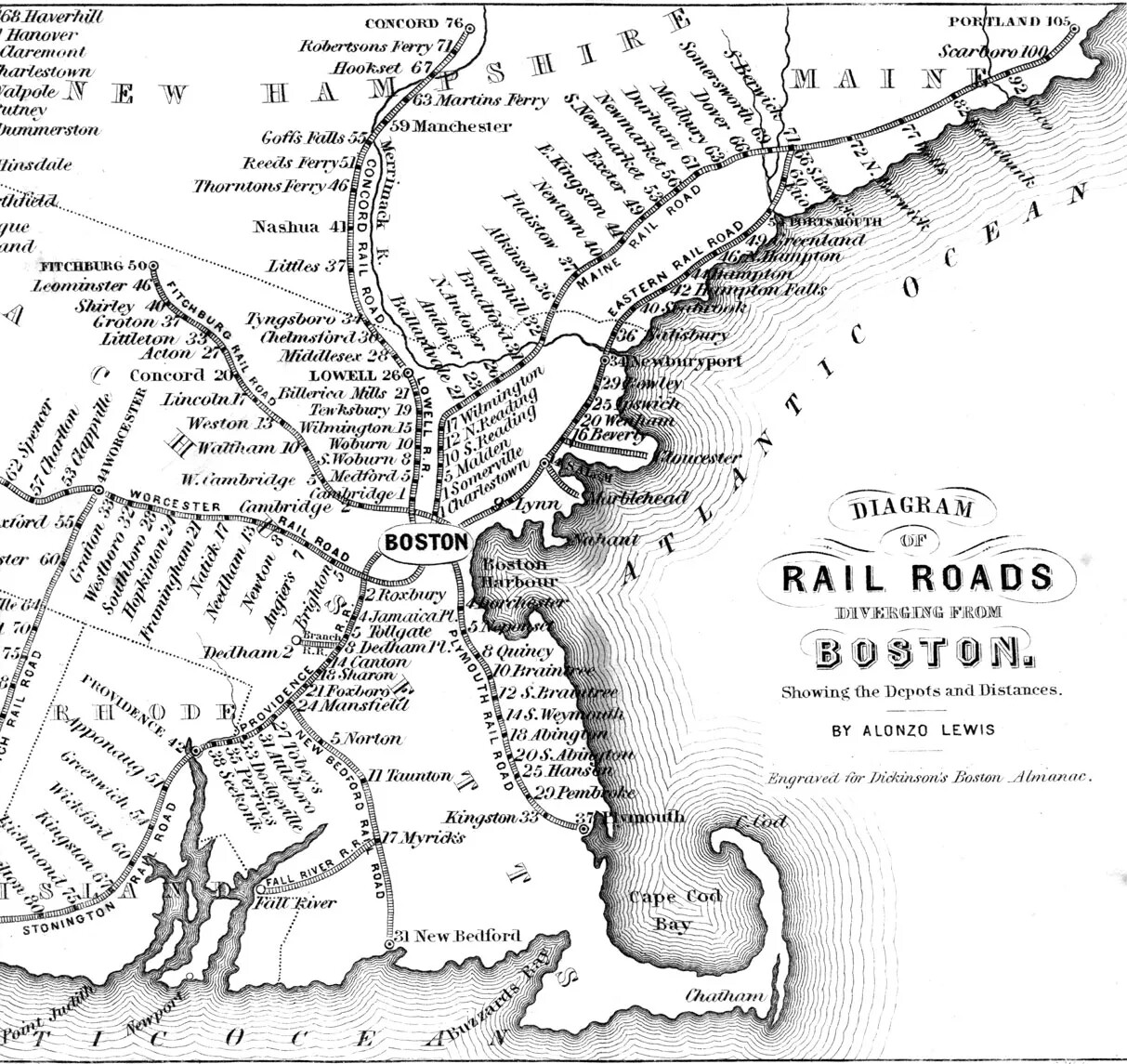

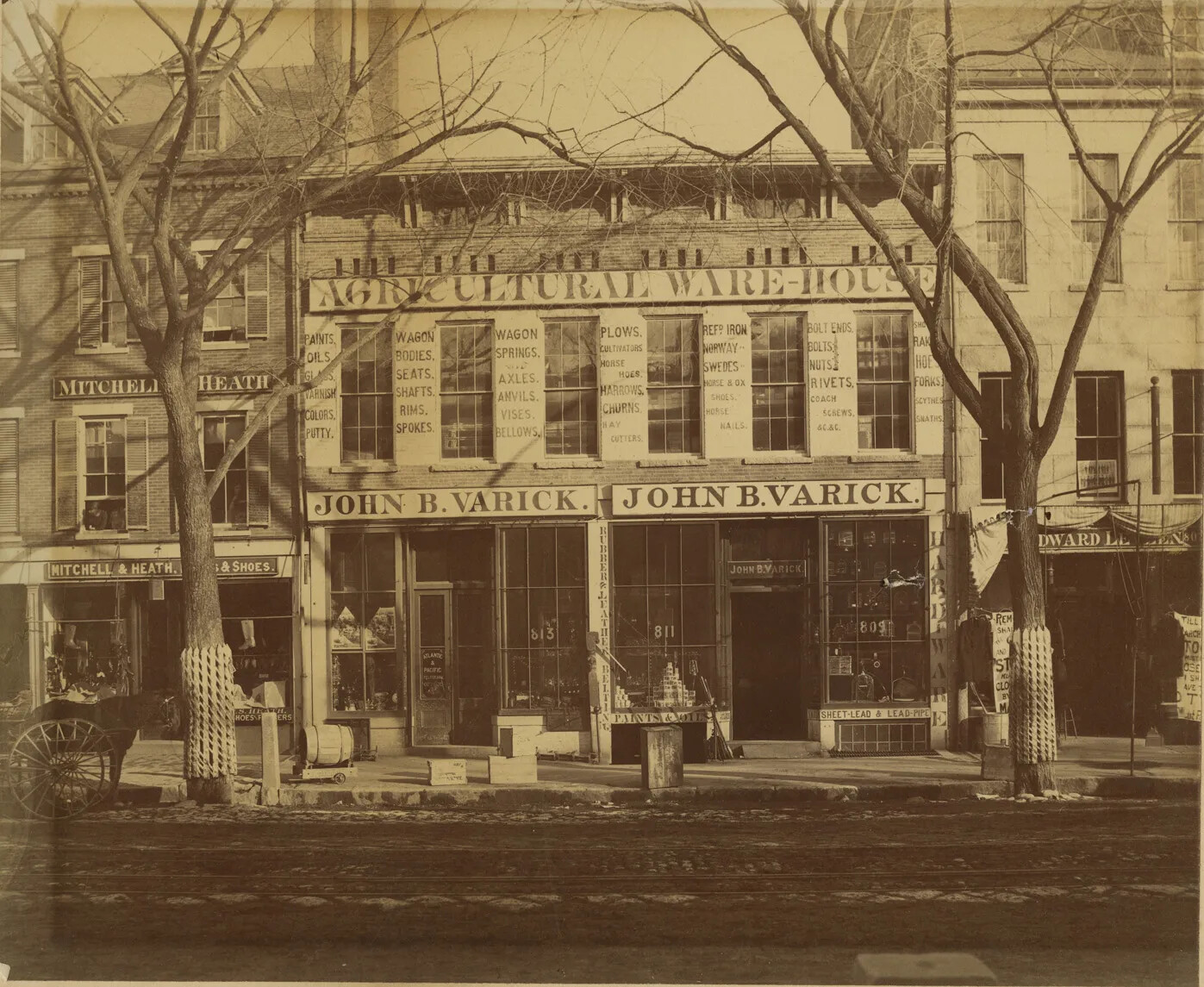

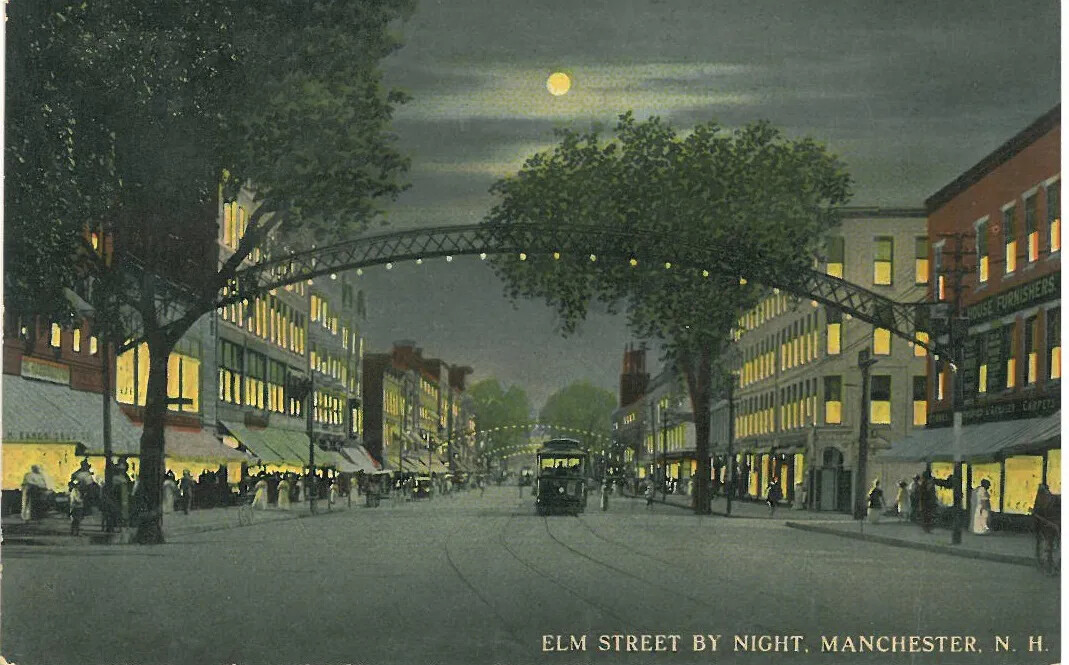

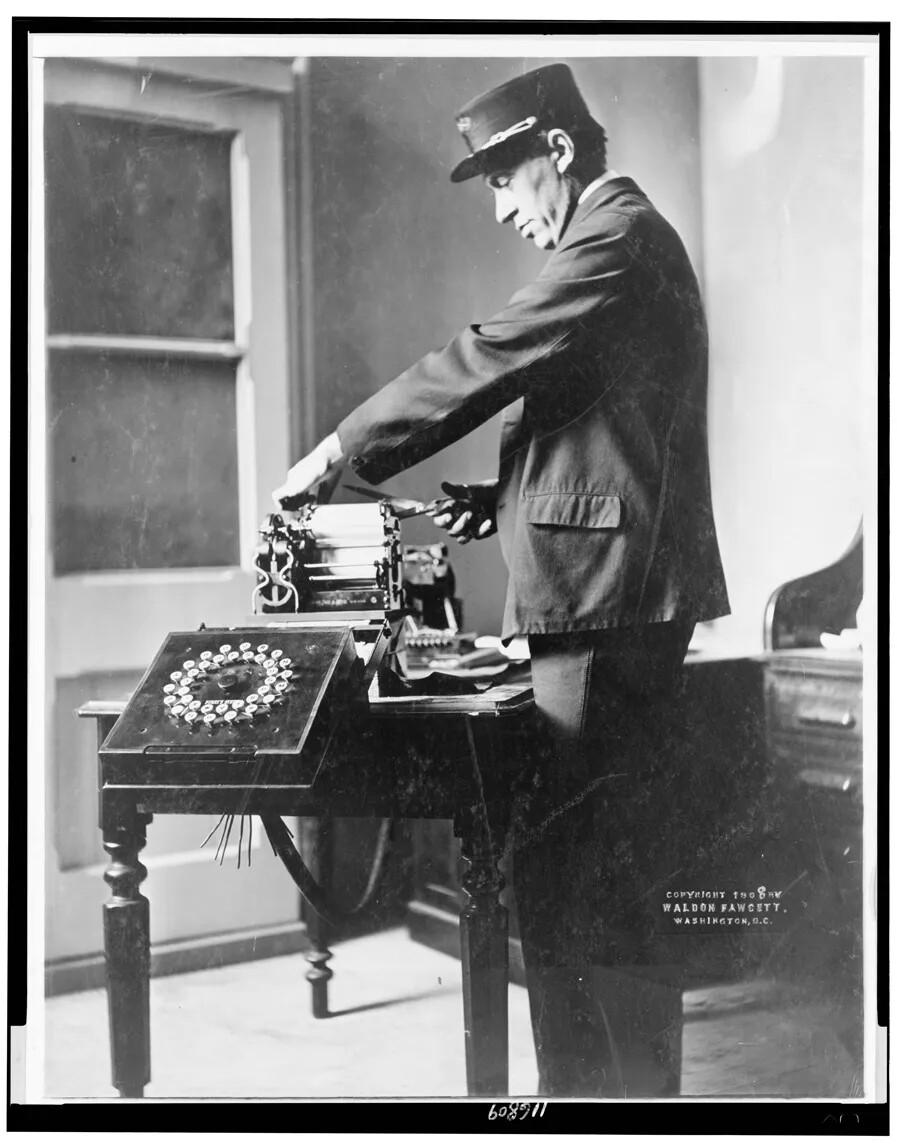

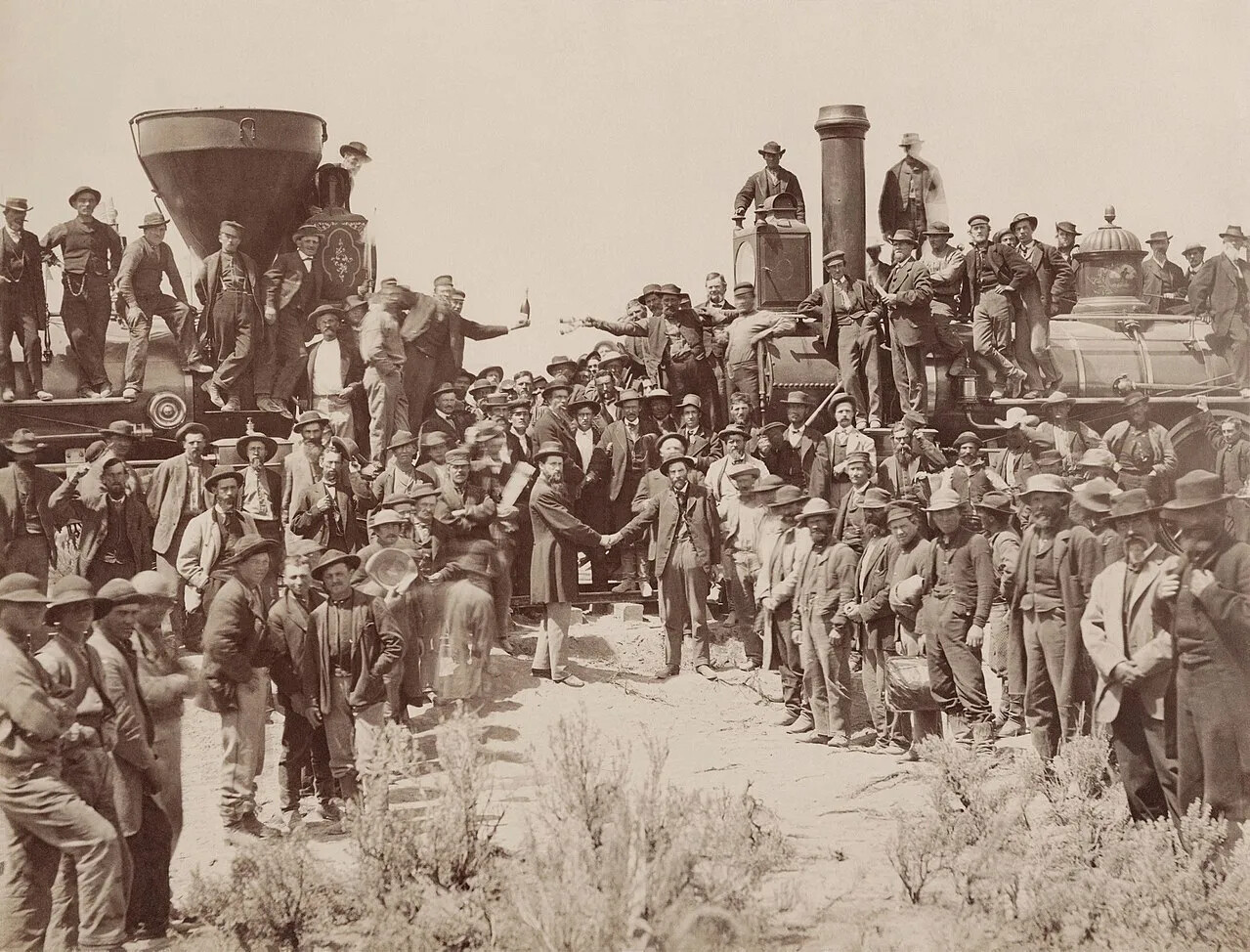

The Industrial Revolution had a big impact on almost everything in people’s lives in the 19th century, especially for those who moved closer to the factories to work in them. All of the people living around the factories made towns grow into cities, with restaurants, shops, theaters, apartment buildings, churches, clubs, and even amusement parks! The cities were linked to one another by transportation networks (like railroads) and communication networks (like telephones). With all these changes to the way people lived and worked in New Hampshire, the Granite State was a very different place in 1900 from what it had been 100 years earlier.

As you learn more about New Hampshire during the Industrial Revolution, think about the following questions:

- How did industrialization change the way people worked in New Hampshire?

- How did people change the way they lived because of industrialization in New Hampshire?

- How did New Hampshire modernize because of the Industrial Revolution?